A cable is simply made of a conductor wrapped in one or more layers of insulation material. While testing conductors, connectors, and end devices is performed in response to specific operational problems, cable condition monitoring is performed to identify degradation in cable insulation material and for cable aging assessment and remaining useful life prediction. Cable condition monitoring is of particular concern in nuclear power plants seeking license renewal to operate up to 60, 80, or more years. AMS provides equipment, training, and services for electrical testing of conductors, connectors, and end devices and troubleshooting to resolve indication issues or equipment performance problems. We also supply electrical and mechanical test equipment to determine the condition of cable insulation material. For more information, please click here.

Cable Aging & Condition Monitoring

renewal.

For electrical testing of cables, the AMS CHAR system performs the following comprehensive set of tests:

Collectively, these measurements help identify and locate impedance problems, moisture intrusion, shorts, shunts, and open circuits along a cable, in connectors, and at end devices. For example, neutron detectors can develop problems in their cables and connectors or within the detector itself. These problems result in erroneous flux indications or false neutron count readings. The CHAR system can identify the location and nature of the problem and guide the plant as to whether the problem is in the neutron detector itself or along its cables or in its connectors.

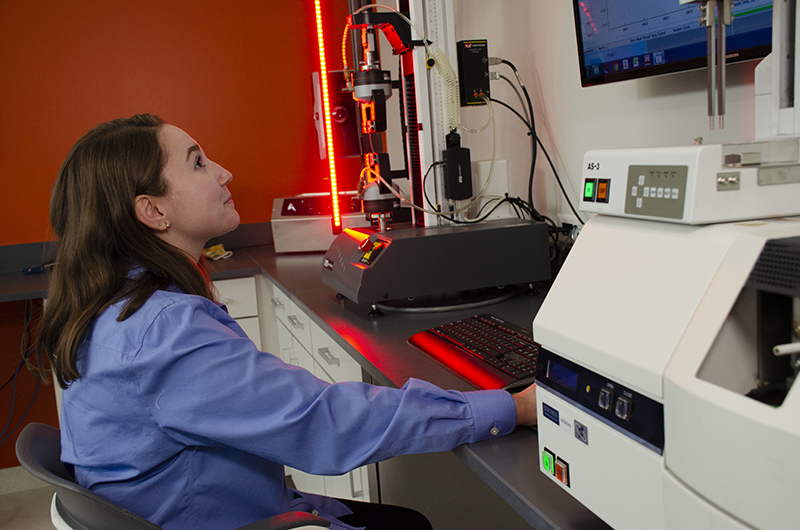

INDENTER FOR CABLE CONDITION MONITORING

For mechanical testing of cable insulation material, AMS provides an indenter unit that is used to measure and track the hardness of cable insulation material. Through an extensive array of laboratory research efforts over a period of five years, AMS has established correlations between indenter modules and the age of a cable’s insulation material. These correlations can be used to verify cable qualification for nuclear safety-related services and to obtain an estimate of the remaining useful life of a cable. For aging evaluation of installed cables in a nuclear power plant, one may perform walkdowns and/or use the electrical tests already mentioned to identify and locate hotspots and then perform indenter testing at the hotspots to characterize the degree of degradation.

CABLE TESTING AND CONDITION MONITORING PRODUCTS

With its CHAR system, indenter, and cable forensics laboratory, AMS provides a comprehensive cable testing and aging management program designed to meet the maintenance, troubleshooting, qualification, and aging management requirements of the nuclear power industry. The first step in this program is to prioritize cables based on safety classification, function, maintenance rules, license renewal commitments and other factors to produce a scope for cable condition monitoring. Field testing with a portable indenter system and/or electrical tests are then performed to assess the health and remaining life of cables. The results of these activities are combined and documented to provide an overall assessment of a cable system’s health.

CABLE FORENSICS TESTING

AMS also offers cable forensic services in our laboratory to provide an in-depth assessment of degraded and failed cables. When damaged cables are identified during field testing, forensic evaluation may be used for root cause determination and to formulate an effective mitigation strategy.

THE FORENSIC TESTS OF CABLE INSULATION MATERIAL PERFORMED AT AMS WILL INCLUDE THE FOLLOWING MEASUREMENTS: