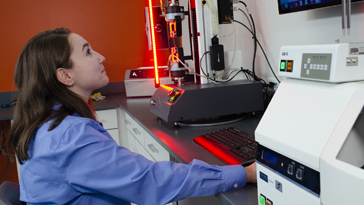

AMS has a state-of-the-art Materials Testing Laboratory providing services to nuclear power plants and other industrial facilities. Using a suite of visual, thermal, chemical, and mechanical characterization tests and analysis tools, our engineers conduct in-depth evaluation of the chemical composition, molecular structure, mechanical characteristics, and physical properties of a variety of materials. This laboratory is staffed by a group of engineers with B.S. to Ph.D. degrees in materials science, chemical engineering, nuclear engineering, and related disciplines.

Materials Testing Laboratory

Over time, age-related degradation can occur in materials resulting in substantial decreases in properties that compromise their performance and functionality. If material degradation becomes severe, it can negatively impact the health and performance of components, equipment, and systems and may eventually cause them to fail. Through years of experience testing industrial materials, AMS’s engineers have developed the expertise necessary to offer materials testing services to support a wide range of industries dealing with aging infrastructure and facilities.

The materials testing services offered by AMS to support these industries in their efforts to ensure their aging facilities continue to operate safely and reliably include:

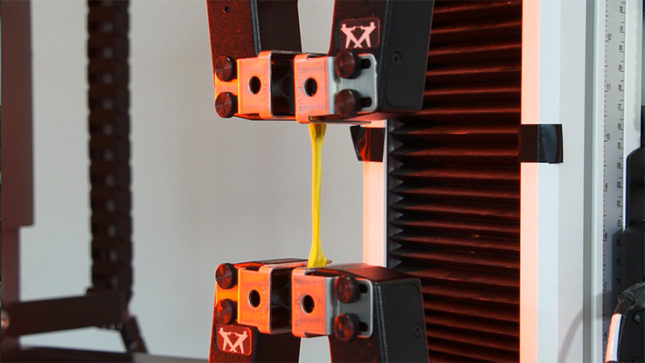

These testing services are offered to evaluate a wide range of polymers, composites, and other materials often used in electrical cable insulation, gaskets, O-rings, seals, electronic components, and mechanical components. These evaluations are conducted using a suite of visual, thermal, chemical, and mechanical characterization tests and analysis tools which are used to analyze the chemical composition, molecular structure, mechanical characteristics, and thermal properties of materials. The materials tests performed in the AMS laboratory are listed below, and more information on each test can be found here.

AMS Testing Capabilities

The laboratory is staffed by a group of engineers with B.S. to Ph.D. degrees in materials science, chemical engineering, nuclear engineering, electrical engineers, and related disciplines. Through years of experience in conducting testing and research and development work, AMS has developed the expertise needed to evaluate aged and degraded materials used in industrial applications.

For more information on the AMS Materials Testing Laboratory and our work with aging infrastructure, please email info@ams-corp.com or call 865-691-1756.

AMS Publications

- A Cable Condition Monitoring Strategy For Safe And Reliable Plant Operation

- Laboratory Testing Results Of Vintage Medium Voltage Nuclear Power Plant Cables

- Application of Condition Monitoring Technologies for Aging Electrical Cables

- Condition of 40-Year Old Naturally Aged Cable

- A Holistic Approach To Testing Cables, Connectors, Shielding, And End Devices In Nuclear Power Plants

- A Cable Condition Monitoring Strategy For Safe And Reliable Plant Operation

- Aging Assessments of 40 Year Old Nuclear Power Plant Cables.