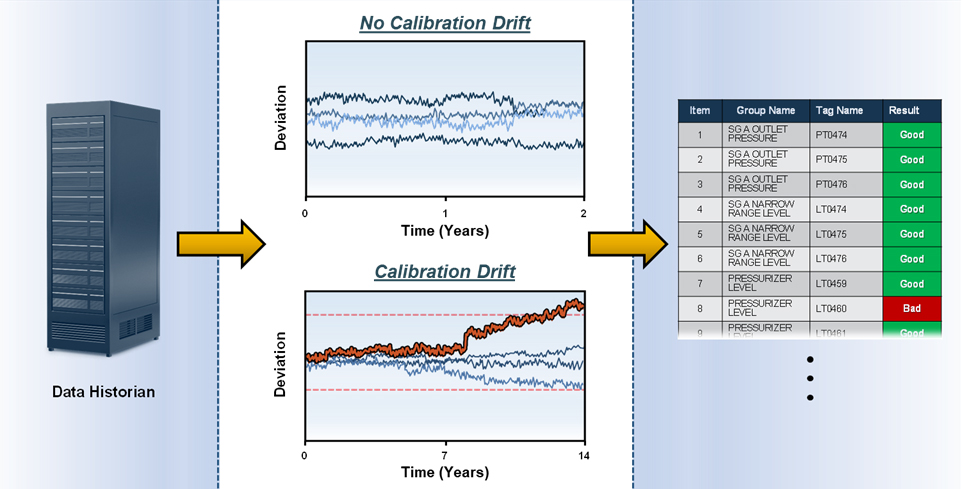

In August 2021, the NRC approved a Topical Report (TR) written by Analysis and Measurement Services Corporation (AMS) to use online monitoring (OLM) technology to extend the calibration intervals of nuclear plant pressure, level, and flow transmitters. NRC approval allows plants to begin the process of OLM technology implementation to drastically reduce O&M costs through condition-based monitoring techniques. Specifically, online monitoring technology accomplishes calibration extension by statistically analyzing transmitter data stored in the plant computer to identify transmitters whose calibration must be checked, and those that can be left alone.

AMS Online Calibration Monitoring

Benefits of OLM Implementation:

In contrast to other methods of extending transmitter calibration intervals like the Surveillance Frequency Control Program (SFCP), the OLM methodology does not require Probabilistic Risk Assessment (PRA) or extensive transmitter drift evaluations and can extend calibration intervals for up to 12 cycles as opposed to the current 36-month extension limitation for the SFCP. Additionally, there is no need for any plant modifications or installation of any new equipment to implement OLM. All that is needed for OLM is already available from the plant computer.

To facilitate outage preparation and planning for a plant with implemented OLM, preliminary data analysis would be provided to the site mid-cycle with formal results submitted within a couple of days after the shutdown of the plant. The methodology is further constructed to utilize existing instrument uncertainties without the need for expensive safety setpoint and accident analysis changes.