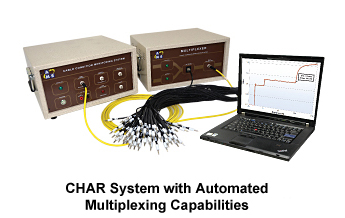

The CHAR Cable Condition Monitoring System measures the health and integrity of a cable by performing a series of non-destructive electrical tests that can be administered from the measurement end of the cable circuit. This allows testing of most cable circuits and end devices while saving test personnel exposure to potentially harsh environments. The data collection is managed by user friendly proprietary software that automatically trends recent measurements with historical baseline data, while flagging discrepancies and outliers.

CHAR Services – Cable Testing for the Nuclear Industry

The CHAR system performs a comprehensive set of measurements to help identify and locate impedance problems, moisture intrusion, shorts, shunts, and open circuits along a cable, in connectors, and at end devices. For example, neutron detectors can develop problems in their cables and connectors or within the detector itself. These problems result in erroneous flux indications or false neutron count readings. The CHAR system can identify the location and nature of the problem and guide the plant as to whether the problem is in the neutron detector itself or along its cables or in its connectors

Typical Cable Problems Diagnosed by AMS:

Frequently Tested Systems

AMS’s experienced team of cable test engineers, through the us of CHAR services, help plants to identify cable issues early, prior to any impact to operability, so that maintenance can be performed proactively. When last minute issues do occur, our team is on call 24/7/365 to support troubleshooting and fault finding activities. For more information on our cable testing activities, please contact us.